There is a little bug in the software of the Arduino Spot Welder. Once the weld counter reaches 10.000 welds the display gets corrupted. This was fixed in V3.2.3.

The problem seems to be caused by the variable types and convertings used in the program. For now to solve this issue in V3.2.3 the weld counter simply does automatically reset to zero after 9999 welds. For future software versions i will try to find a solution so the counter can count to values over 10.000 reliably.

You can find a tutorial how to update the Spot Welder Software here: Software Update Tutorial (just use new V3.2.3 instead of 3.2.2 used in the tutorial)

V3.2.3 of the Software can be found here: Github Page

Solution for the problem without doing a software update

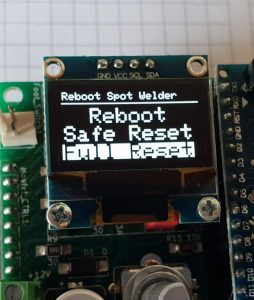

In the older software versions you can solve the display problem by doing a “Full Reset” in the system menu. This way you manually reset the weld counter to 0. Then you can do 9999 welds before the problem occurs again. An instruction how to use the system menu is in the Quick Start Guide

Hello

Can You supply the Arduino Nano With the pre-installeed software 3.2.3

Regards Lionel

Yes i can do that. Please write an email to info@malectrics.eu if you would like to buy one.

Man, thank you for the great product!

One BIG WHISH!

Please include an adaptor / fuse for Dewalt Li-Ion batteries.

Many people have Dewalt \ Bosch \ Milwaukee as their daily tools and having ability to power up from them would be amazing. I am pretty sure this will be the next BIG break through in the project development!

Those batteries have 18V and high capacities up to 9ah. Much better than buying an extra power source.

Dennis.

These devices usually use 18650 cells. For example 18V 9Ah packs should be 5s3p

The cells are not rated for the very high current the welder needs.

A 5000mAH Turnigy NanoTec Lipo can do 130C max which is about 130×5 = 650A

The Bosch/Dewalt etc. packs can do max 3C if its a very good one maybe 10C.

That would be “only” 90A max current, which is plenty enough for all home tools, but not enough for Spot Welding.

Can this program be used to control the transformer?

You could use just the Arduino Board and attach an SSR relay to the mosfet driver output, which then controls the primary side of a transformer.

But it may need some additional protection circuit to not damage the Arduino board.

Hey guys/gals! Njfulwider5 here, I recently got my hands on one of these welders and to tell the truth EXTREMELY PLEASED!!! When I first turn on the welder it read software 3.2.3. So this just means if I’m reading correct once the welder hits 9999 welds, with this version 3.2.3, it will

Reseat to 0 automatically, nothing I need to do on my part? Also I noticed the board says version 3.2. Does that mean the board is capable of using car batteries of anything higher than 800cc? Last question, hopefully not a stupid one! Is it safe to leave your battery connected to the welder if you added a power switch on the red wire going to the positive side(fused). Thanks for anyone’s help, should see my video I made a pretty cool battery for mine using SPim08hp. Loving this little welder!!!!

Thanky you for the positive feedback.

To answer your questions:

1. From software 3.2.3 it will do the automatic weld counter restet when 10.000 welds are reached.

2. V3.2 mosfet board should not be used with batteries above 800CCA. V3.3 mosfet board has better current handling capabilities but i still do not recommend to use stronger batteries since this stresses the mosfets and the protection diodes a lot.

3. With a sitch in the thin red positive wire you can leave the welder connected to the car battery. Just make sure to put some isolation on the tip of the positive welding cable so it can not accidentaly touch the negative battery terminal or any components on the welder.