There is a new Version 3.1 of the Spot Welder available. It has a little improvement on the mosfet board that makes it possible to use higher CCA car batteries -> more welding current. Read more to find out the details.

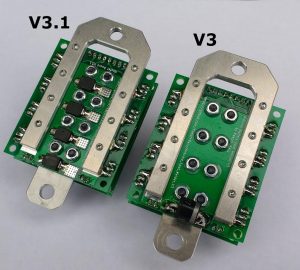

Difference between V3 and V3.1

While the “old” V3 can handle 400…600CCA car batteries reliable the new V3.1 is now capable of handling up to 800CCA car batteries.

The restriction in the car battery size was not due to the IRFB7430 mosfets. These can handle an absolute maximum of 1400A pulse current. It was the TVS diode that basically has to clamp almost all the welding current to ground for a very short time (few micro seconds) at the end of each welding pulse. Since each pulse consists of 2 pulses, a short one to heat up and clean the weld spot and the second real welding pulse, the TVS diode has to “protect” 2 times on each pulse. If you are now using a higher CCA car battery usually the pulse time will need to be set lower because of the higher current. This does stress the TVS diode even more because it has to take the higher current in a shorter time periode as compared to using a lower CCA car battery where the TVS has to take less current and has a longer periode of time between the pulse ends.

The improvement in V3.1 is that it uses 4 TVS diodes in paralell on the mosfet board instaed of one in V3. The through hole TVS diode in V3 (5KP13A-E3/54) has an absolute maximum current rating of 600A. The SMD TVS diodes (5.0SMDJ13A) do have an absolute maximum rating of 300A each. So with some reduction because of paralell use calculated in, the 4 SMD TVS diodes should be capable of handling about 1000A.

When builing the Spot Welder yourself make sure to use 4 TVS diodes from the same batch or at least from the same order. This will ensure that theire specs tolerances are pretty close to each other so the current is spread evenly across the 4 diodes. If you are using maybe 2 old diodes you already had laying arround and 2 new ones it can happen that e.g. the old ones open earlier as the new ones. Then they take all the current and will fail.

Recommendation

Although it is now possible to use up to 800CCA car batteries i would still recommend to use only 400…600CCA batteries. These deliver enough current to weld 0.15 to 0.25mm nickel strips which should fit most applications and it will stress the components on the Spot welder much less than a super powerfull 800CCA car battery.

Hi,

just wonder why most battery powered spotwelder designs use TVS diodes to protect MOSFETs from voltage spikes instead to use freewheel/flyback diode connected in parallel to welding leads?

TVS are eating/wasting energy from current decay, flyback can reuse the energy in welding current path. Or did I miss something?

Hi,

In the earlier versions of the spot welder i used a flyback diode in combination with a TVS diode to get rid of the voltage spike. Because in theory flyback diodes are recommended for this and should work. But then i got an oscilloscope and could do some measurements. These showed that the TVS diode has the main effect on reducing the voltage spike amplitude and duration. The “voltage spike” was only about 5-10% shorter if the flyback diode was added adiitionaly.

hi i am trying to build one my self . can u recommend a through hole type of diode to use instead of smd for v3.1 also for smaj13a ( do u think p4ke13a is good enough ) ? and 5.0SMDJ13A replacement ?

congrats for ur project.

Instead of the SMD TVS diodes you can use 5KP13A-E3/54 for example.

The samll SMAJ13A diodes dont need much power. These are just to protect the mosfet gates from electrostatic discharge.

Just make sure the breakdown voltage is above 14V which is the maximum voltage of a fully charged car battery.

Clamping voltage should be about 20 V.

Hi!! I have build v3.3 version and after with 3ms probe welding the IRFB7430 BOURNT.

I use a car batery 77Ah 760cca.This is problem the car batery so strong??

Please help me resolve this problem

Thanks in Advance

Robert

hi, at this low pulse time the mosfets should have no problem with the high current.

I tested with a 800CCA car battery and 6ms pulse time for a few hundred welds already.

After how many welds did your mosftes fail ? Maybe you did the welds to quick or they overheated.