There is a new version V2.2 of the prebuilt kits available. It got some amazing new features and pcb upgrades.

Whats new in V2.2:

- Mosfet PCB now with 2oz copper layer and wider traces which connect the high current carrying mosfet legs to the u-shaped aluminum part

- little bit bigger mounting holes for u-shaped aluminum piece (2.6mm instead of 2.5mm)

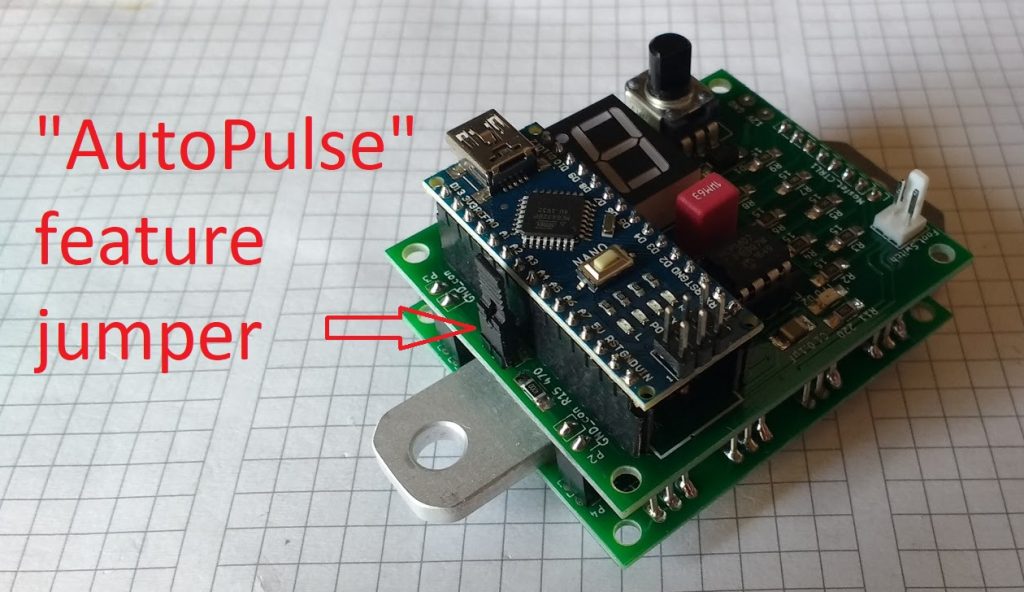

- “AutoPulse” feature, which automatically activates a pulse after a 2 second delay when both welding tips touch the nickel strip (thanks to Petr Zverina for the idea)

- upgraded Mosfets to IRFB7437 (they can handle up to 1000A welding current with no problem)

- u-shaped aluminum part is now riveted to the pcb

The biggest upgrade is the “AutoPulse” feature. It is now integrated, so you can choose if you want to use the foot switch or the “AutoPulse”. It automatically activates a pulse after a 2 second delay when both welding tips touch the nickel strip. If activated you can not use the foot switch to activate a pulse. To deactivate it simply remove the Jumper next to the Arduino.

Only improvement I’d like to see is the height or position of the potentiometer and display unit. Both fitted higher than Ardunio board to allow easy fitting to a flush box face.

Or on both on a remote PCB with ribbon cable.

Great project for a compact, easy to use spot welder for home/hobby purposes.

Ideas for thought:

– consider making the Schottky a standard option

– use the 12V car battery to power the board itself

– use the arduino to check the probe voltage prior to discharge (to see if no 12 v are on the probe indicating a shot mosfet)

Well done!